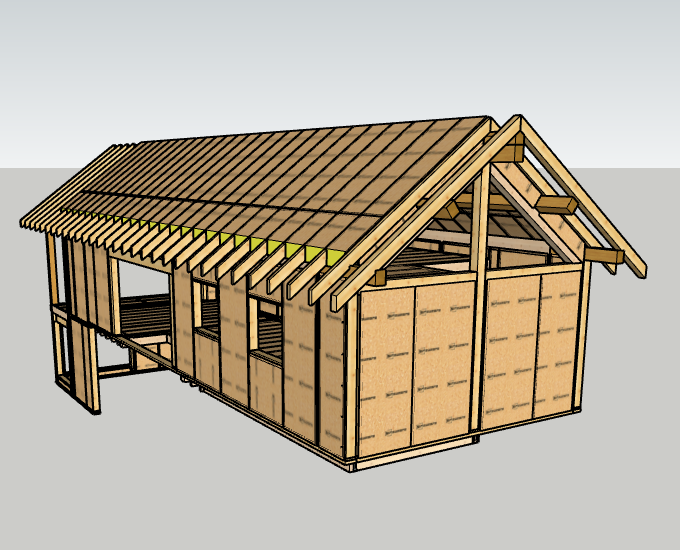

Structural Insulated Panel (SIP) & timber frame construction solutions

Flexible solutions for simple or complex, traditional or modern designs. SIP structures, prefab and steel elements, CLT (cross laminated timber), integrated post & beam, CNC processing, modular design or a hybrid. In-house design & structural engineering to adapt your plans for a SIP / timber frame solution.

DESIGN FLEXIBILITY

MINIMAL WASTE

EU CERTIFIED

MORE SPACE

HIGH STRENGTH

NEGATIVE CARBON FOOTPRINT

COST SAVINGS

FAST CONSTRUCTION

ENERGY EFFICIENCY

SIP panels

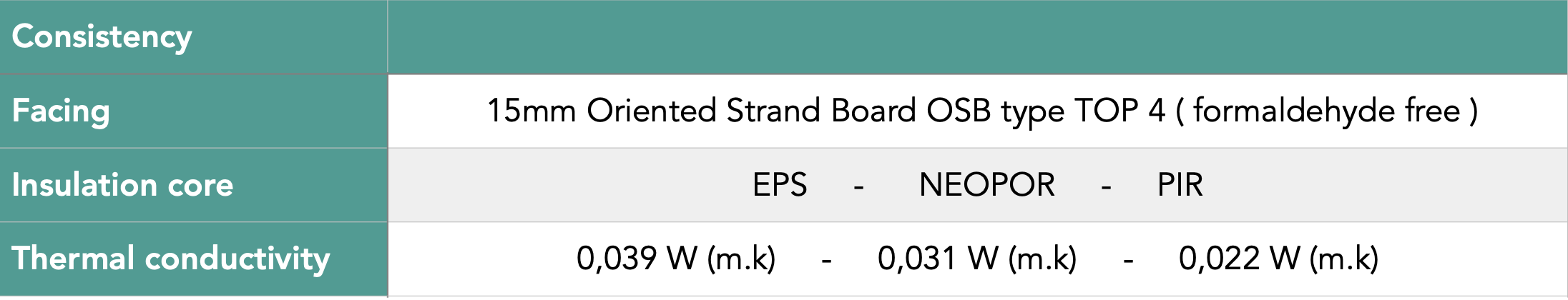

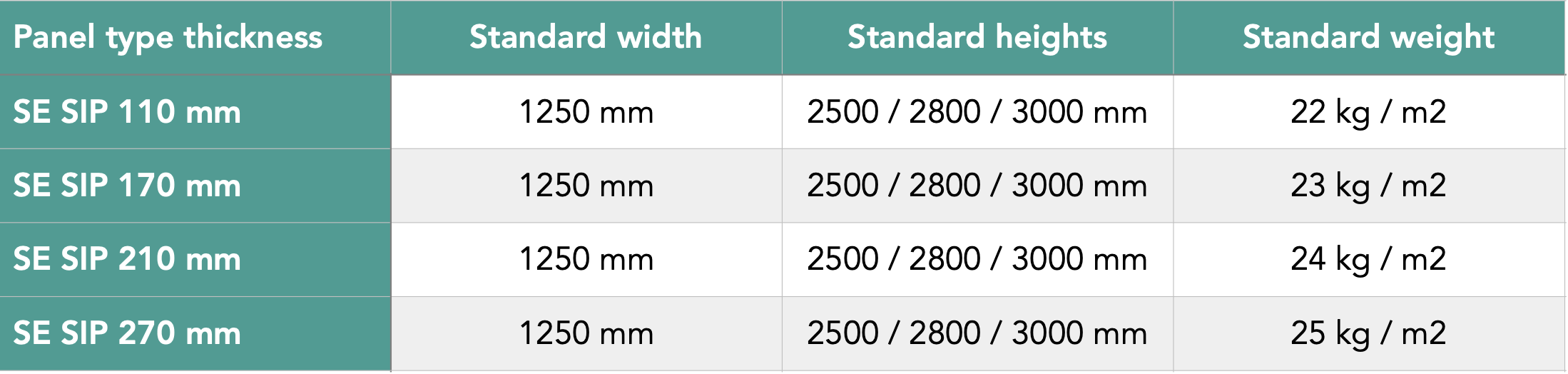

The panel consists of two OSB TOP4 boards and between them an insulating core of expanded flame-retardant polystyrene EPS, EPS with graphite or PIR.

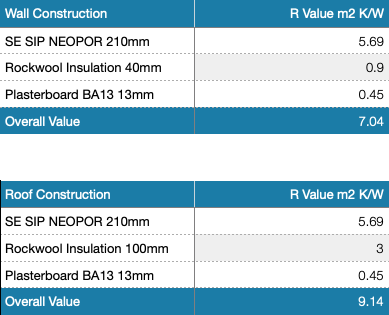

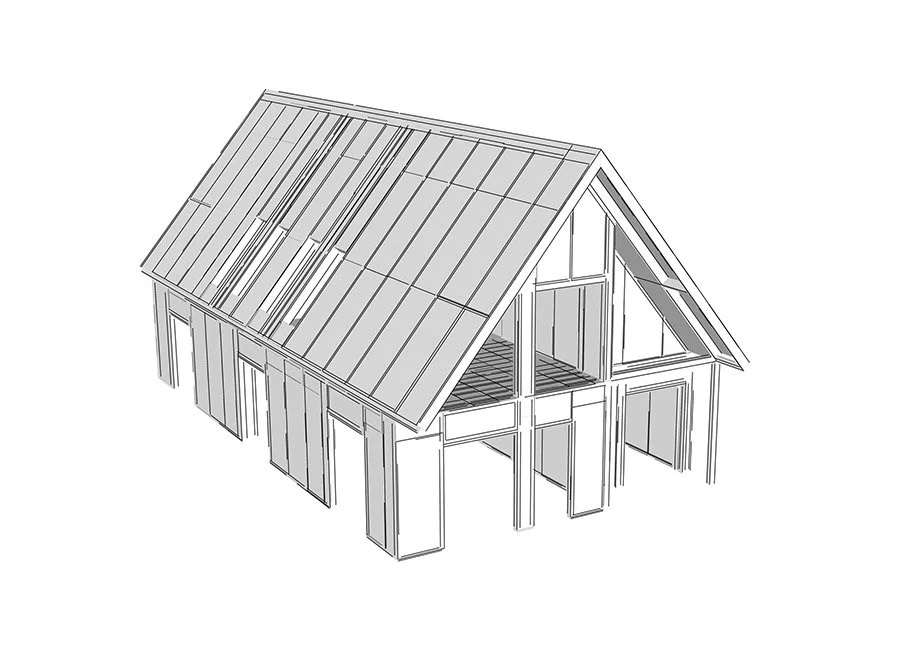

These are precision engineered and cut in the factory for fast installation on site. The panels boast excellent thermal insulation properties, low bulk density and high structural rigidity.

A SIP building is classed as timber frame but is much stronger as the panels themselves are structural, thermal bridges are greatly reduced and it achieves top scores in the air leakage test required by RE2020.

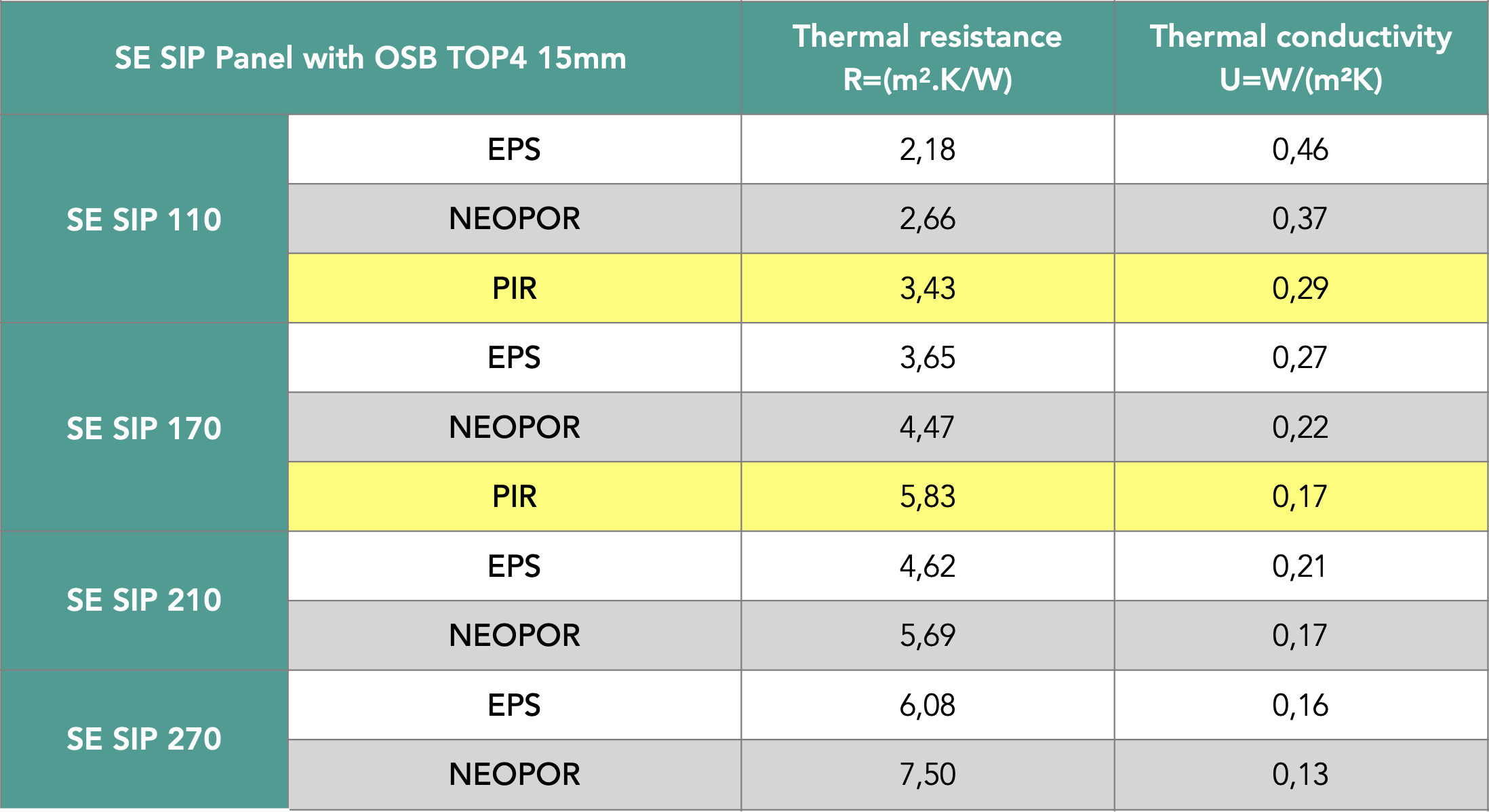

Panel options

SE SIP (expanded EPS polystyrene core): Mainly used for internal walls.

NEOPOR (graphite polystyrene core): Our most popular product, these panels contain high-purity graphite particles which give the insulation a reflective property that increases the energy efficiency of the panels and decreases the carbon footprint.

PIR (Polyeurothene / polyisocyanurate core): Premium thermal resistance, if your project needs more insulation from a thinner panel.

Timber frame

Traditional or modern - SIP buildings offer complete flexibility of design. We use certified KVH and BSH structural timber in strength class C24 and up to GL24h, wooden bonded I-joists or CLT (Cross Laminated Timber) panels. Combined with traditional carpentry we can create homes in any style with exposed beams, or create a completely modern look with large open span CLT unsupported floors.

Design options

Structural timbers

Standard:

Solid pine

Upgrade:

I-beams (lightweight, allow services to pass)

Traditional carpentry on exposed structure

CLT floor

Types of wood

Standard:

Pine

Upgrade:

Visible-grade pine

Glulam pine

Glulam larch

Solid larch

Solid oak

Douglas fir

Brushed / baked / burned

Easy fit out

The SIP structure is quick, flexible and easy to fix to for all tradespeople.

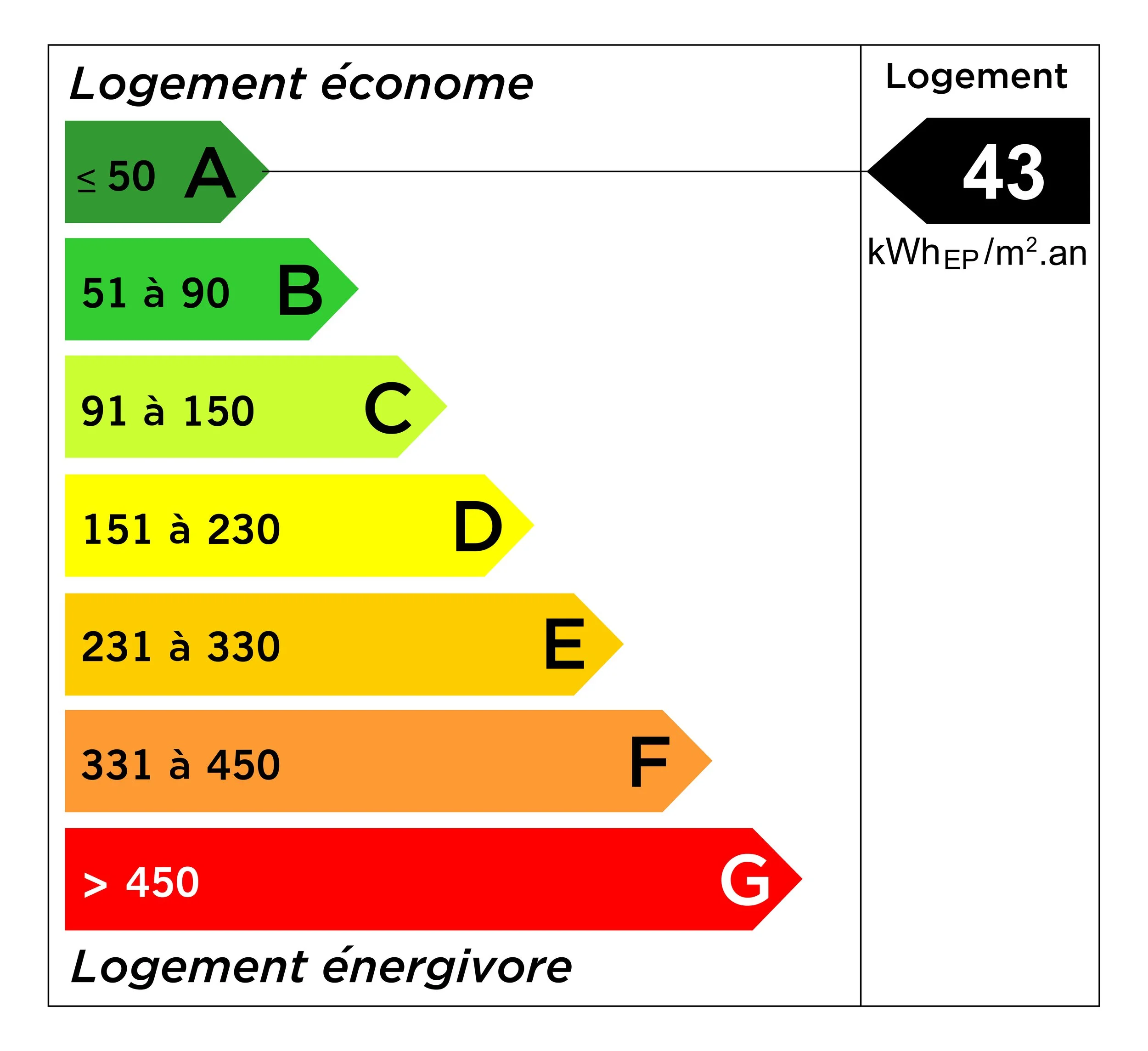

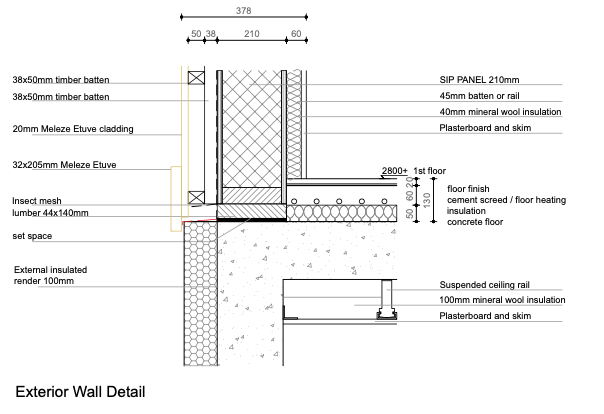

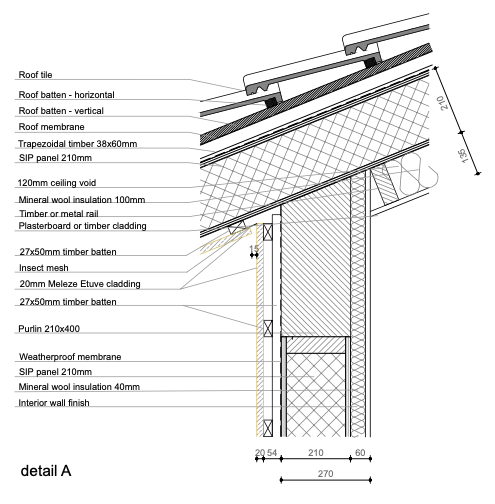

The internal face of the external walls are quickly battened out ready to receive plasterboard, and for the creation of a service void to accept cabling & electrical back-boxes, which can be infilled with Rockwool insulation as part of internal fit out. A service void in the ceiling should also be created to accommodate lighting, ducting etc and this can be filled with insulation during internal fit out, resulting in R values that easily pass French RE2020 rules.

In-house engineering

Structural calculations

Full structural calculations to Euro-codes with point and sheer loads provided early in the process to enable accurate concrete engineering.

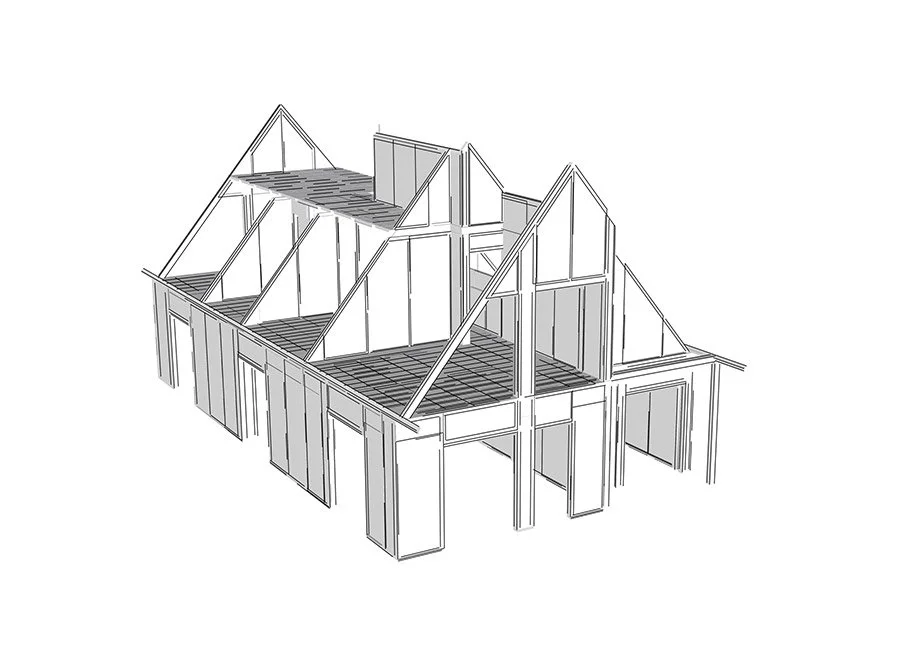

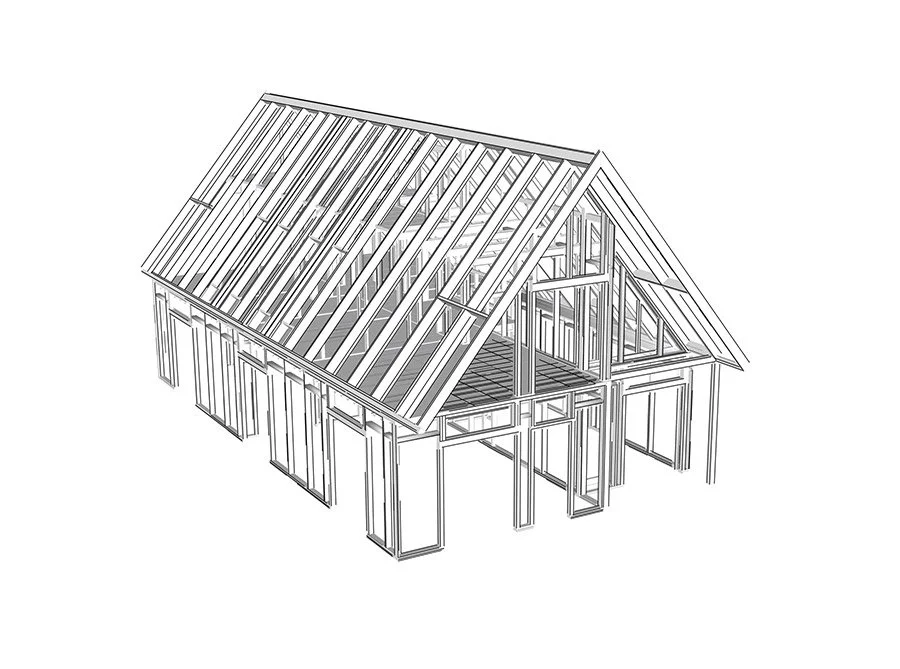

3D modelling

Detailed 3D modelling accurately showing all components, fixings etc. Model can be used by follow on trades and for detailed design and execution plans.

Easy installation

Detailed assembly plans & materials list provided as well as ongoing support and training.

Installation

Our French-registered teams have over a decade of experience building with SIPs in France and oversee the engineering process to ensure conformity with French building codes. We also offer consultation for follow-on trades and standard construction details for internal fit out of SIP structures.

Alternatively, one of our certified representatives can oversee install by your own local construction team. Once your team have completed one install with training from our representative they can carry out further installations themselves.

Training & certification

Contact us for information on training and certification for your construction team to install SIP Europe structures.

Request a quote

To receive an initial estimate with 90-95% accuracy please send your plans with full dimensions in PDF or DWG format. Our engineers will create an initial 3D model of your project to quantify materials.

Our estimate assumes we will be given detailed drawings and engaging with an architect/project manager/developer. Detailed design services are available in addition if required.

Estimates have a 3-week lead time. If the estimate is acceptable we request a deposit payment before proceeding with full structural calculations and detailed design. This takes around 8 weeks and once agreed we can book in production and be on site within weeks.

Tell me more…

-

The EPS foam insulation has zero Ozone Depletion Potential and does not contain or release gases harmful to the environment.

Our suppliers use OSB made from fast-growing trees so the timber is more quickly replaced and, because they are structural and stronger than traditional timber frame, the use of SIPs to create the building envelope significantly reduces the amount of timber needed.

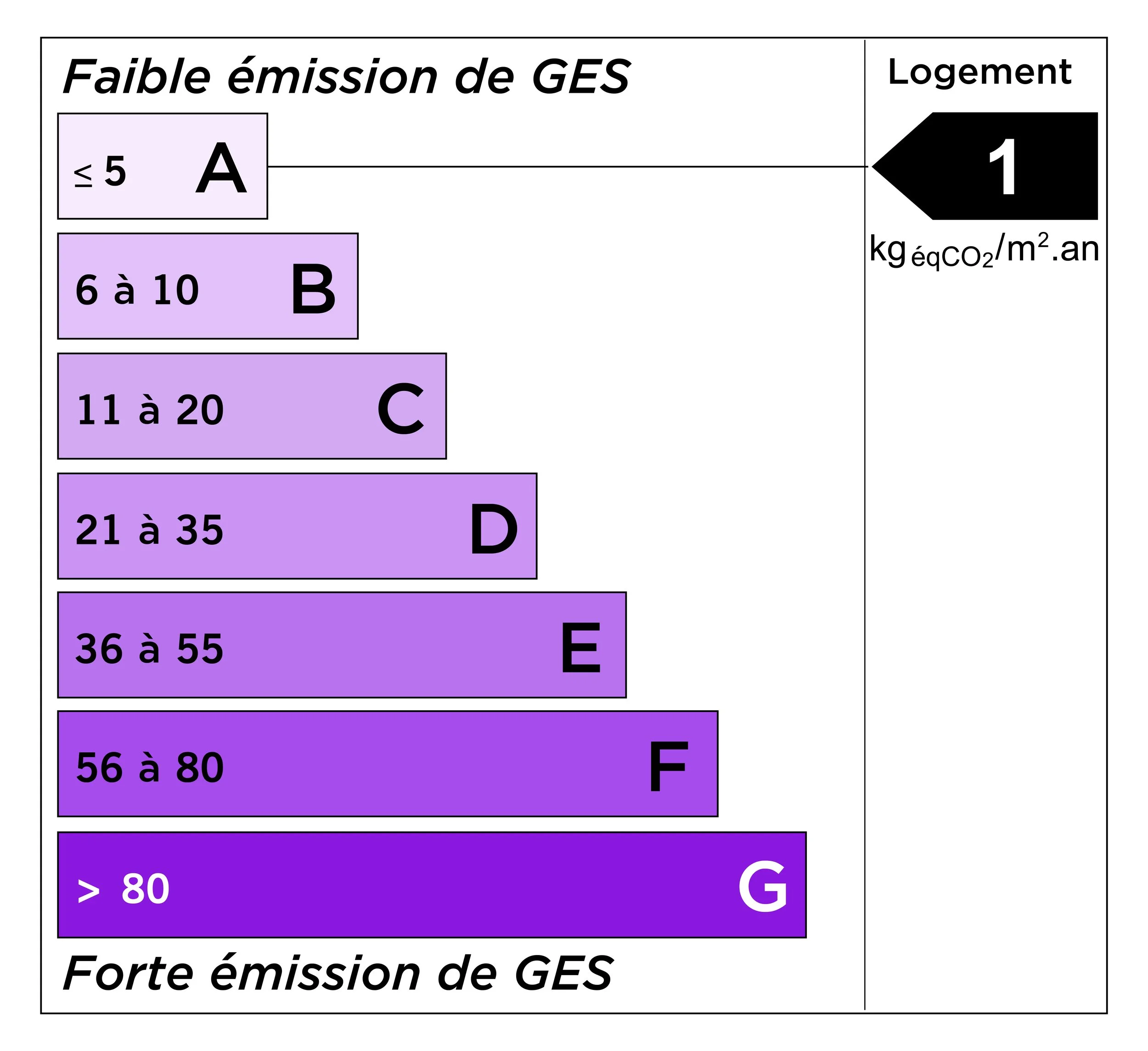

The SIP structure itself has a negative carbon footprint due to the manufacturing process and the use of recyclable materials. The panels create a fully airtight structure which is highly insulated and loses minimal heat. When combined with eco systems such as mechanical ventilation and heat recovery systems, underfloor heating, Canadian well, triple glazing, solar, shutters/blinds, reflective glass and air source heat pump, SIP structures can become almost passive buildings with minimal heating bills and energy usage.

-

The expanded polystyrene (EPS) insulation and oriented strand board (OSB) used in the manufacture of SIPs meet the highest standards for indoor air quality. SIPs do not contain gas or any volatile organic compounds (VOCs) - chemicals that can adversely affect health inside the home. The EPS used in fact eliminates HCFCs and HFCs, which are ozone-depleting VOCs released into the air by some other types of insulation.

A SIP structure creates a completely airtight shell with much more effective insulation properties (indicated by the higher R-value/lower U-value) than traditional timber frame. This allows control of indoor air quality, using mechanical ventilation and heat recovery systems, and the engineering of a building that’s healthier to live in.

-

SIP structures perform well in blocking and absorbing sound, including high frequency noises that can impact quality of life.

Tests on a 170mm SIP panel found it blocked sound by - 31 dB, and a standard outside wall (made up of 100mm rockwool + 170mm panel + 12mm gypsolinium board) blocked sound by - 45 dB.

-

The expanded EPS core of the panel is flame-retardant, adding to your peace of mind in the event of fire.

-

The materials are ETA certified for use in Europe.

Recent projects

Eco envelope solutions

Integrated solar roofing

Combining traditional metal roof or roof tile design with cutting edge solar technology, all integrated into your roof finish with options for traditional or modern styles.

High performance windows & doors

We partner with various manufacturers for wood or aluminium frames, specialising in triple glazing, solar, automated shutters & blinds as well as large or trapezoidal openings.

Eco partners

Our partnerships with eco-focused architects and project managers across France allow clients to access design and site coordination if required. Whether your project needs additional expertise or you’re interested in partnering with us, let’s chat.